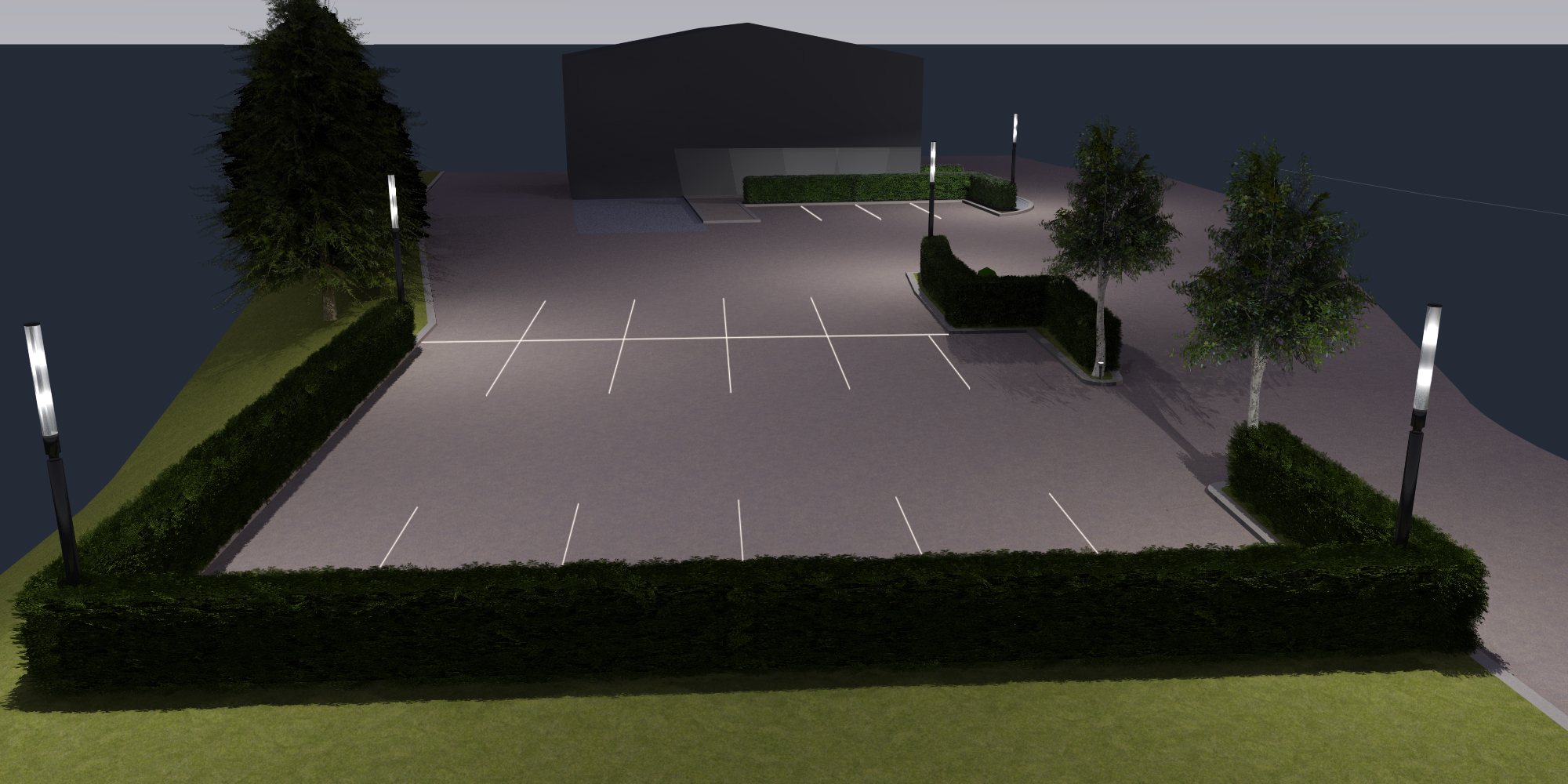

As space becomes more and more a precious commodity we must ask ourselves how we can utilise the effectiveness and space we must work with. This applies to the construction of car parks where new and innovative techniques must be used to maximise the effectiveness for a car park whilst only being in a small space. Here are some ways to maximise the efficiency of a large concrete or tarmac car park in our modern times.

1) Diagonal Car Parking

Now you may be surprised by this thinking that the ordinary straight style of car parking spaces is the most effective method to maximise space however, this is false it is the diagonal option. The maths behind it states that a diagonal configuration no matter what situation will always be more especially aware and fit more vehicle spaces in a car park than the rectangular configuration. This reasoning has lead.

2) Have Defined Car Park Exits and Entrances

We all have experienced the que to get in a car park that only has a one way exit and entrance system and we have all experienced the frustration this has caused. Well obviously, this method is not an effective method of organising a carpark because the more congestion in the car park means less cars being able to park and leave. This can be Solved by embedding clear exits and entrances at opposite ends of the car park so a clash between exiting vehicles and entering vehicles cannot occur.

3) One-Way Aisles

Now this may seem inefficient and a recipe for disaster however, with the combined use of defined entrances and exits this can be a very effective method of traffic control in the carpark. This method ensures that oncoming traffic cannot occur therefore eliminating all aspects of reversing backwards to allow right of way.

4) The Interlock Method

If your car park is on the bigger size and takes advantage of the grid car parking method then you should certainly be thinking about revaluate this method to the interlock method. This method includes using the diagonal method one after each other to maximise the number of car parking space to create an efficient space that is easy to use and allows easy flow of vehicle movement.

Keep an eye out for more of our surfacing and civil engineering tips and advice.